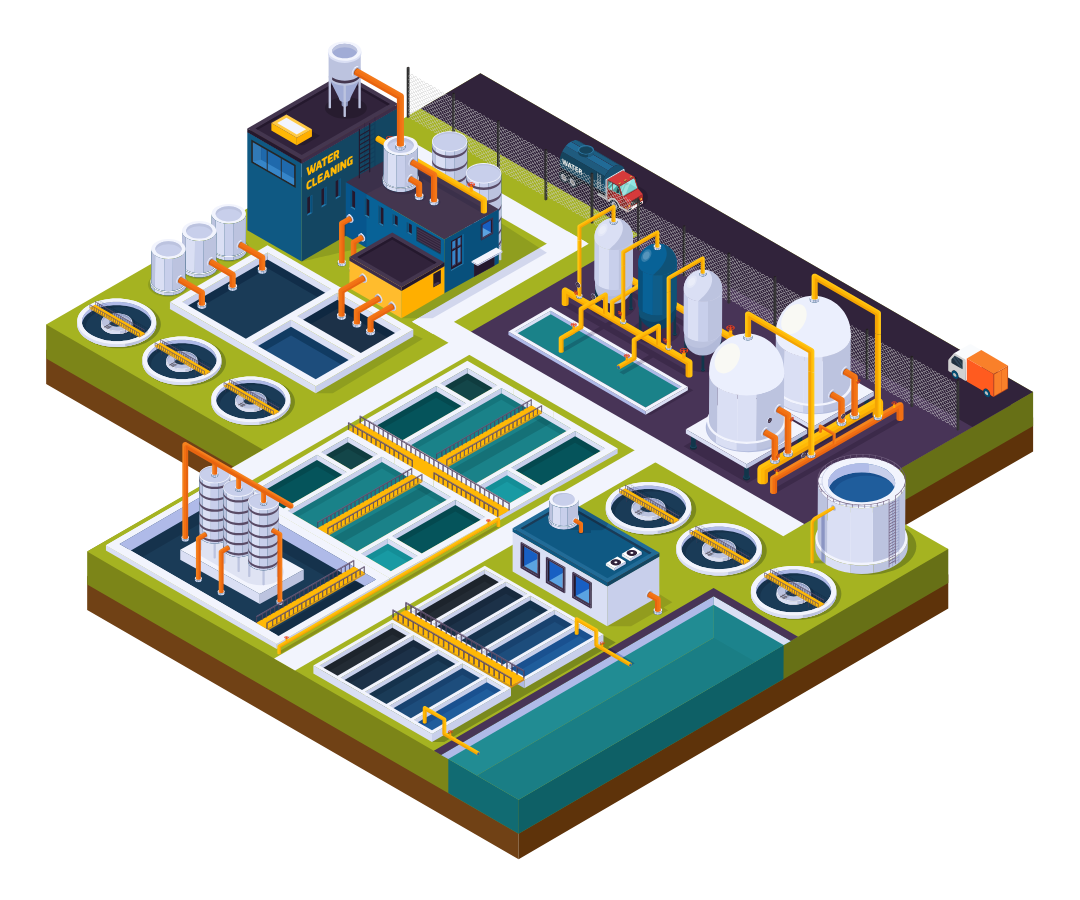

Mono Water Treatment designs its projects not only to meet today’s needs but also to address the requirements of the future. It carries out comprehensive feasibility studies on critical aspects such as process analysis, capacity determination, energy efficiency, water conservation, and environmental impacts. With full compliance to national and international regulations, it develops flexible, scalable, and long-lasting solutions through proper equipment selection and modular architectural principles.

Design – Engineering

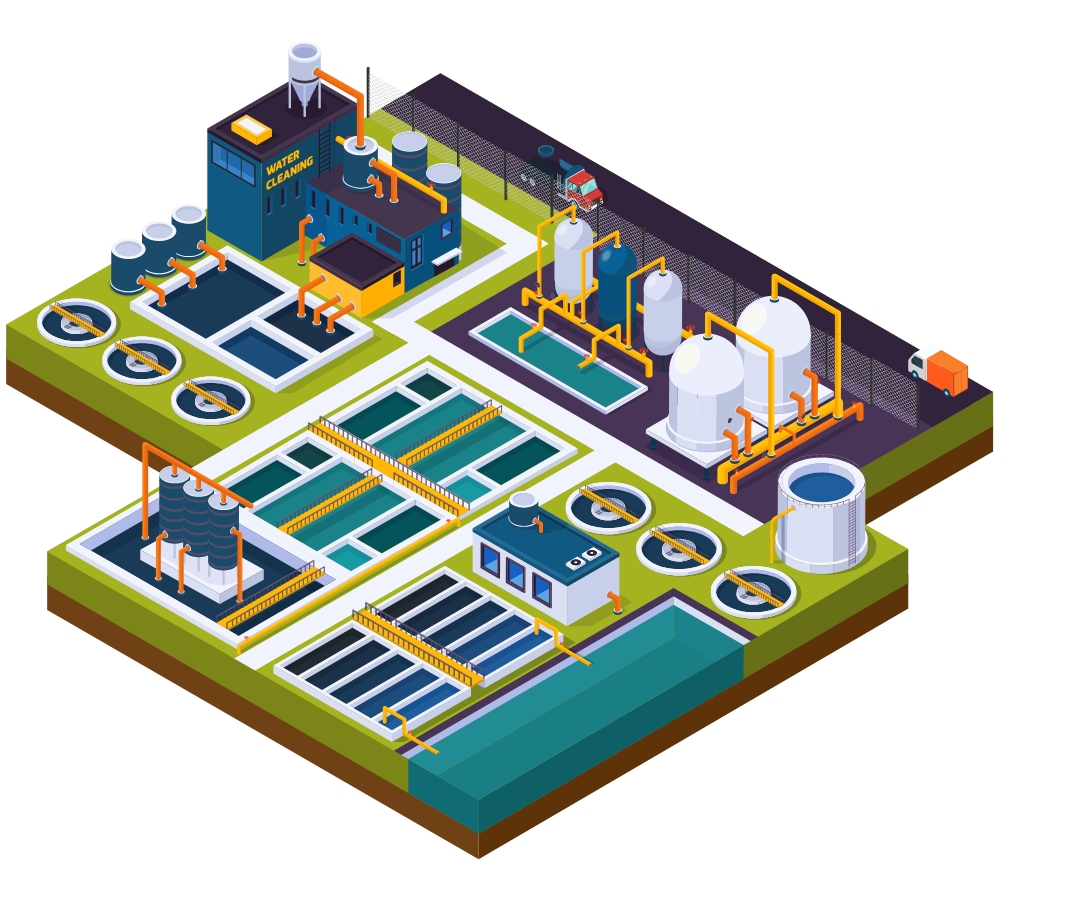

Equipment Supply and Manufacturing

The performance of treatment systems is determined by the quality of the selected equipment. For this reason, we work with world-class brands and, when necessary, carry out project-specific manufacturing. Pumps, membranes, filters, control panels, and automation components are selected according to performance and durability criteria; through precise workmanship, high-quality materials, and multi-stage quality control in production, we deliver systems that operate safely and reliably for many years.

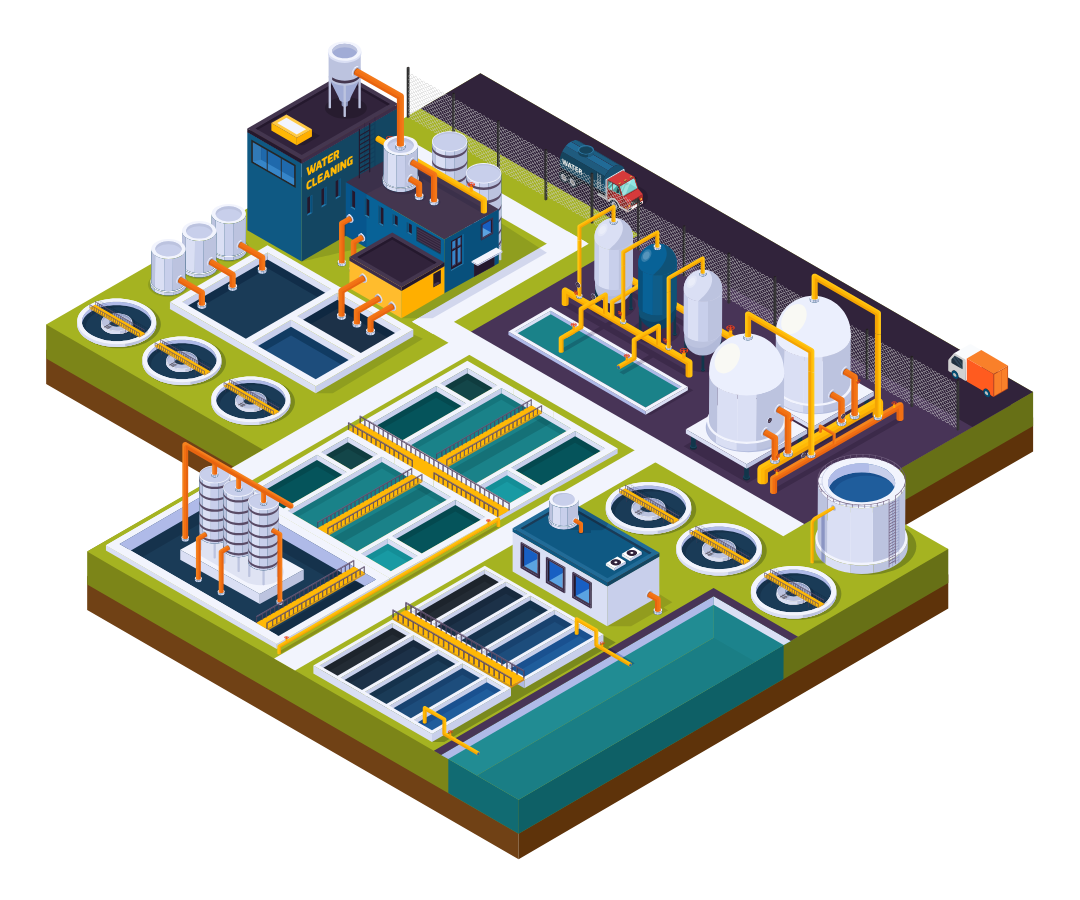

Installation

We carry out installations in a supervised and safe manner, in full compliance with occupational safety procedures. Mechanical, electrical, and automation connections are completed in accordance with the project layout plan, ensuring accessibility and ease of maintenance. After installation, all connections and flow scenarios are tested to minimize potential risks, while order and cleanliness on site are carefully maintained.

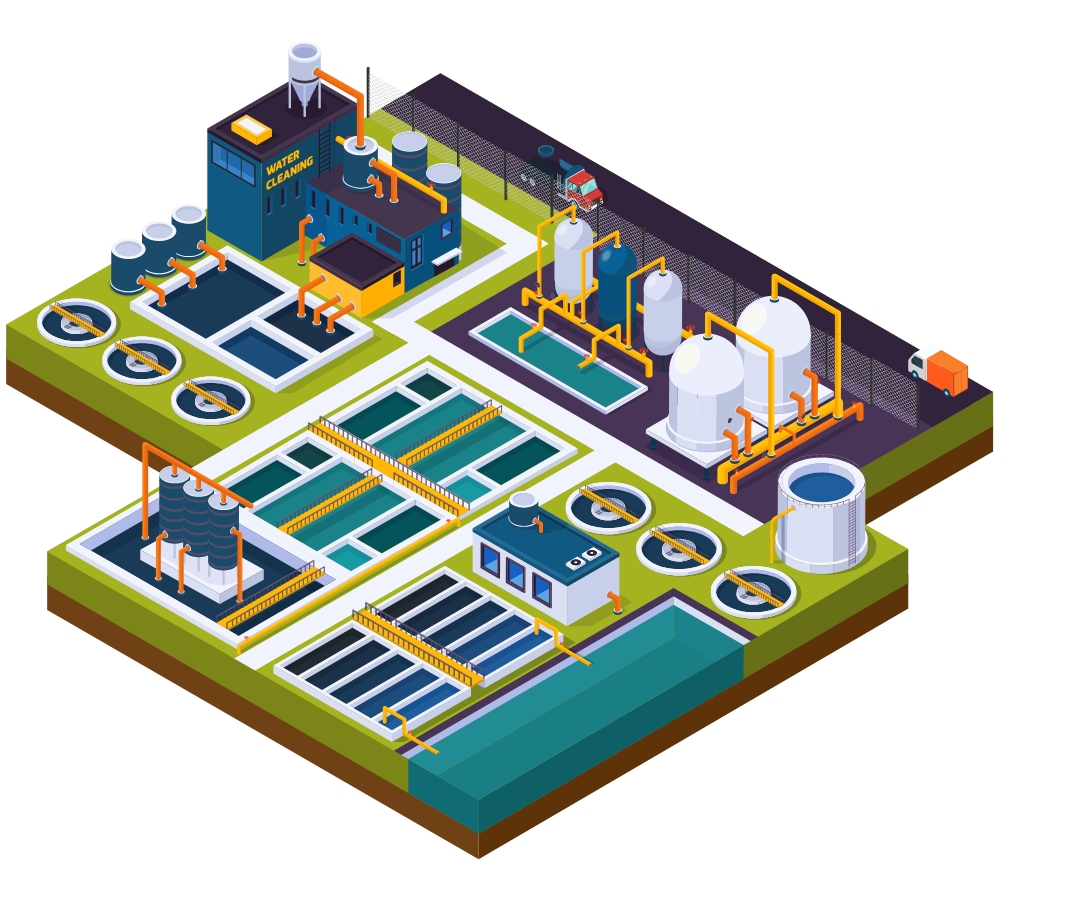

Commissioning

After installation, the system parameters are optimized to achieve maximum efficiency from day one. Process tests, water quality analyses, energy consumption measurements, and control settings are verified under different load conditions. The results are reported in detail, and system performance is documented before being handed over to the user.